- Materials -

Carbon Fiber , Advanced Composite Explained.

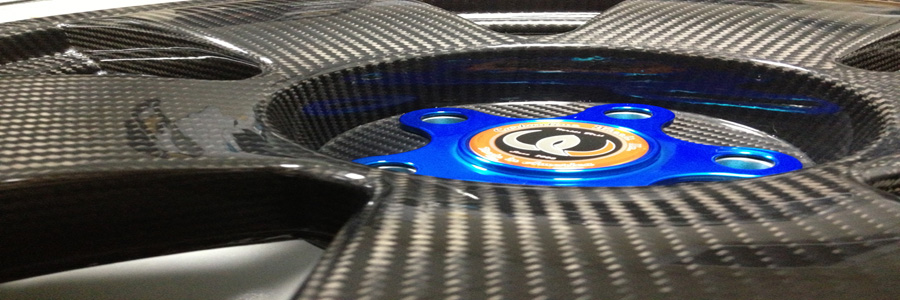

Carbon fiber can be described as very thin, strong fibres and is generally used to reinforce composite materials, particularly the category of materials known as carbon fibre or graphite reinforced polymers. It is also known as reinforced plastic or carbon fibre composites. As a compound, it's admired for being stronger and lighter than fiberglass. It is of much importance to designers and engineers due to its sturdiness. It's a kind of material that is lighter than aluminum and stronger than steel. It's amazing.

Carbon Fiber is composed of carbon atoms that are bonded together to form a long chain. These carbon fibers are extremely stiff, strong, light and are the top choice for many processes to create excellent building materials. Carbon Fibre material comes in a wide variety of raw building blocks such as yarns, weaves, uni-directional, braids and many others which are used to manufacture advanced composite products.

Carbon Fiber Reinforced Plastic (CFRP) is an extremely strong and lightweight material that is gaining increasing popularity with engineers and manufacturers. In tension strength, for a given weight of material, it's at least 4.5 times stronger and stiffer than any steel, aluminum or titanium in the industry. Carbon fibres are very thin strands of carbon which are much thinner even than a human hair. Individual fibers are corralled together in what is known as a carbon fiber towline.

A towline can have between 1,000 and 50,000 individual fibers in the bunch. This towline material is then woven and/or stitched together to become different carbon fiber woven cloth materials. The towline can also be used by itself (filament winding) to manufacture certain parts. The step between these dry towlines, fabric woven cloth materials and a finished solid material is the introduction and curing of a resin to turn the carbon fiber into a CFRP.

The Benefits Of Carbon Fiber , Advanced Composites.

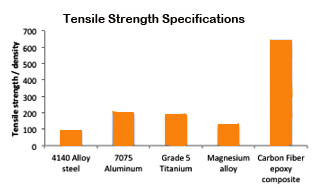

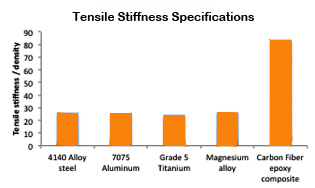

These specific properties of a CFRP are a direct comparison to those of popular high performance metals in the figures chart below.

- High stiffness to weight ratio

- High strength

- Corrosion resistant

- Fatigue resistant

- Energy Absorption on Impact

- Tailored material properties

Generally a carbon fiber and/or advanced composite part design has its own unique schedule of layers and orientations of carbon fibers to form the desired ratio of stiffness, weight, and strength. These are just some of the highlight benefits of the futuristic material known as carbon fiber and/or advanced composites. Another outstanding benefit to carbon fiber is it's thermal soak properties. In other mediums, such as metals, the choices are much more limited. With carbon fiber advanced composites, they are limitless. As we keep moving forward with reseach and development, we are finding that by hybriding other reinforcement materials along with other resin base systems there are no limits to achieving the perfect manufacturing materials.

The advantages of carbon fiber materials are significant. First of all, carbon fibers are very light fibers which results in lightweight structures. Furthermore, one can chose between stiff or strong fibers depending on the composite part being produced and the type of carbon fiber material required. The exceptional impact properties make carbon fiber advantageous in various industry segments. During an impact, carbon fibers disintegrates (metal instead would simply deform) which can make it is a very efficient energy dissipation mechanism. Although carbon fiber is fairly expensive compared to other more common fibers like fiberglass, the price is steadily decreasing due to the progress of production technology. Another major advantage is that it's thermal expansion is basically zero. An example would be that metal expands when heated while carbon fiber remains in its basic form. For specific projects where thermal stability is required, carbon fiber can be a tremendous benefit. The material can resist very high temperatures (1000 Celsius). Carbon fiber composite structures do not suffer any fatigue issues if designed and engineered properly. Finally, carbon fiber is permeable to X-ray and does not corrode, which is a huge issue with metals

Fatigue

When it comes to aluminum and other metal products, usually these products are not going to fail because of a single catastrophic load due to the property values of aluminum or metals. But because of small, repeated stresses each stress load cycle on an aluminum or metal product, however small, puts that material that much closer to a fatigue failure status. Designers and engineers realize these limitations and therefore over build their products for a lifetime of use. When properly designed and manufactured carbon fiber , advanced composite materials have an almost infinite fatigue life. These property values mean that designers and engineers now no longer have to "over build" parts to deal with fatigue as is done with aluminum components leading to even lighter products. Carbonline Wheels practice all of the necessary steps to assure that we build a perfect carbon fiber wheel by performing Finite Elemente Analysis (FEA) for reassurance the integrity of carbon fiber orientation lay-up schedules. CLW also performs White Light Scanning for actual physical measurement data.

Corrosion

Metals are highly affected and degrade due to corrosion. Another advantage of carbon fiber reinforcement materials is that it is not affected by corrosion which is why Carbonline Wheels llc.are not subject to the adverse affects of corrosion like metals are. The fact that they do not degrade via these mechanisms means that designers and engineers do not have to account for degradation caused by corrosion throughout the products life. This again provides further opportunities for weight saving and efficiency gains in vehicles and reduced through life costs. When manufactured with the appropriate resin systems, carbon fiber is one of the most corrosion-resistant materials known.