Carbonline Wheels llc. - TECHNOLOGY -

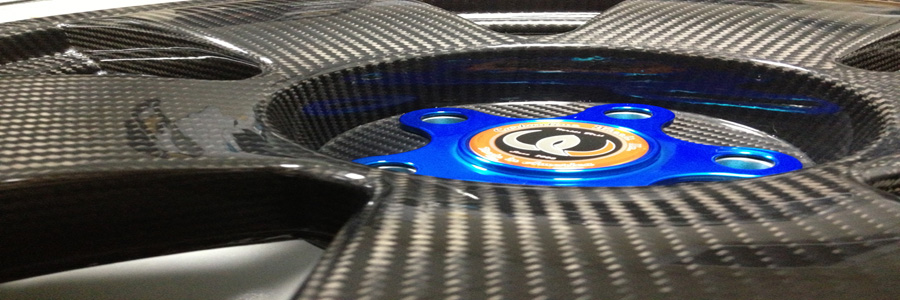

CARBONLINE WHEELS llc. has been rigorously in product development for over a decade of time. Carbonline's founders have been at the forefront of advance composites. CLW has owned and operated a variety of other composite prototyping companies and advanced training schools. CLW has over 40 years of composite, carbon fiber experience and knowledge. Carbonline's carbon fiber wheels are a precise, focused masterpiece.

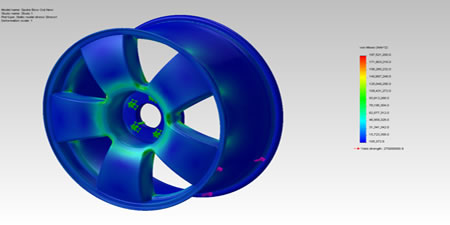

Carbonline Wheels begins their designs in a computer aided design (cad) with a couple of different software programs (solidworks and catia). When this step is performed, CLW creates a three dimensional model and focuses on the design cues which were previously free hand sketched while staying true to the design intentions. A model is produced for a variety of reasons. A few of these reasons are for visualization and discussion purposes. Designers can use the model to create three dimensional renderings, investigate production scenarios and also investigate component metrics such as weight and/or moments of inertia to predict performance figures. Carbonline now processes the wheel through a Finite Element Analysis (FEA) Optimization program. This very advanced software simulates all the load factors that a wheel would be subjected to in real world conditions.This computer software makes it possible to simulate demanding thermal and/or mechanical operating scenarios such as simulating driving over curbs, how much heat the carbon fiber wheel can handle, driving through a 2g' corner and more. The model can show where the wheel will have the most stress in areas by shades of color in the model. One of the advantages of this software is that if the model can show signs of excessive stress loads in an area. The model then can be modified and corrected before manufacturing a physical part.

Next, Carbonline Wheels creates a computer aided machining (cam) file from the previously (cad) file. Here the wheel model is converted into a g-code which now can be read from cnc machines. This process is completed again by using very advanced software. After the g-code is completed a medium material is prepared and set up on a cnc machine. Parameters are programmed to the cnc machine and eventually the wheel is manufactured to be a physical part.

Carbonline Wheels is constantly performing (WHITE LIGHT SCANNING) digital measuring to assure consistency. Whether it be the tooling or the part itself, CLW scans every product that we are working with to assure it for accuracy and consistency.